THE EVOLUTION CONTINUES

The new EVO™ 600 and EVO™ 6000 represent the next step in the evolution of Automatic Tank Gauges. Evolving with the changing needs of station owners and operators, the EVO™ 600 and EVO™ 6000 provide new capabilities to make fuel management even easier for every user.

ALL NEW FEATURES

The EVO™ 6000 and EVO™ 6000 ATGs provide highly accurate inventory management and full-featured compliance monitoring for any size fuel system – plus advanced features like Corrosion Control™ System automation and monitoring, Electronic Line Leak Detection, and DEF/AdBlue® recirculation. Check out all of the new features available on the EVO™ 600 and EVO™ 6000.

We are driven by our pursuit to innovate, simplify, secure, and connect every station owner to their fuel management system. EVO™ 600 and EVO™ 6000 ATGs feature simple setup and operation, remote connectivity, and advanced security features to protect your fuel system while keeping you directly connected to vital site data whenever, and wherever.

Highly Capable

EVO™ Series ATGs keep your site in compliance and protected from security threats with customizable user roles, user activity tracking, and up to 3-years of data back-up to protect against power outages or other system interruptions.

Simple Interface

A full-color 7” LCD touchscreen serves up one of the most intuitive user interfaces available with simplified user features you won’t find anywhere else.

Secure Data

EVO™ Series ATGs keep your site in compliance and protected from security threats with customizable user roles, user activity tracking, and up to 3-years of data back-up to protect against power outages or other system interruptions.

A full-color 7” LCD touchscreen serves up one of the most intuitive user interfaces available with simplified user features you won’t find anywhere else. You choose your home screen, you program your product colors, and you choose what shows up on your Favorites screen. Customize the interface to meet your business needs the way you operate. Check out the interactive demo below.

CLICK ON THE INTERACTIVE TOUCHSCREEN BELOW

![]()

Icon-Based Design

Designed to be understood easily and operated intuitively. It’s simple to operate for new users and can reduce the amount of training required to operate.

One Touch Buttons

You can customize these home screen buttons to automate and carry out anything from complex, multi-function processes to simple daily delivery report generation – all with the touch of a single button.

Quick Jump Menu

Navigate quickly from application to application with ease. This time-saving menu makes the interface’s structure extremely shallow, simple to navigate, and reduces the amount of steps it takes to accomplish tasks.

EVO™ Series ATGs help keep sites in compliance while providing marketers with the highest level protection from the security threats facing our industry.

Unlimited User Roles

Unlimited, customizable user roles and log-in security features protect against unwanted access while keeping track of user activity.

Data Protection

The latest in industry standard TLS/SSL protocols ensure data encryption between web browsers and the ATG.

Integrated Wifi

Optional integrated Wifi allows secure and protected onsite viewing of inventory levels for fuel delivery drivers.

Turbine Pump Interface is a powerful tool that creates a network between your Submersible Turbine Pump (STP) controllers and EVO™ Series ATGs. Through TPI, the tank gauge can be programmed to respond to faults in the submersible pumping system and react with intelligence that pump controllers alone cannot.

Pump In Water Automation

When the water level in a tank approaches the pump intake, the tank gauge will enter alarm mode and automatically shut down the pump, protecting the system and consumers from water being pumped from that tank.

Leveling & Priority Modes

When managing two storage tanks of the same product ‘Leveling Mode’ can keep both tanks at the same percentage full without the use of a syphon bar between the two tanks.

Remote Pump Interaction

By networking the intelligent controllers to the fuel management system via TPI, a technician can remotely connect to the site to review the logged event history and view the status.

EVO™ 600 and EVO™ 6000 ATGs offer additional advanced features and capabilites to manage your entire system as efficiently as possible.

AutoLearn™ Technology

Patented AutoLearn™ electronic line leak detection capability including Statistical Line Leak Detection for high throughput sites.

Corrosion Control™ System

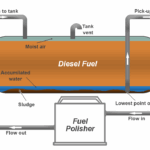

Proactively monitor for and remove corrosion-causing water from your fuel system with system automation and monitoring powered by EVO™ 600 or EVO™ 6000 ATGs.

Streamlined Setup

Hardware auto-detection and wiring confirmation, multipoint tank charting, network printer auto-detection, and the ability to download and upload entire programming profiles from one ATG to another.

Improve dispenser throughput and maintain fast flow rates with the ability to detect and react to potential slow flow issues before they impact business with Flow Rate Monitoring. Available as a software option on new EVO™ Series ATGs or as a field upgrade option, Flow Rate Monitoring delivers ongoing flow rate performance data, flow rates for each fueling point, and provides a notification if transactions dip below a user-defined set point.

Know Your Flow

Monitor for and ensure fast and consistent dispenser throughput with daily reports and alarm notifications regarding flow rate performance.

Performance Monitoring

Sales and dispensing duration data are automatically reconciled to help you better understand the flow performance of every fueling point.

Proactive Maintenance

Often, slow flow rates can indicate that a dispenser filter needs to be changed. Be proactive in calling for maintenance, getting dispensers back to peak performance sooner.

The EVO™ 600 and EVO™ 6000 are compatible with the Corrosion Control™ Water Separator and Corrosion Detection Sensor, allowing owners to fully automate the removal of corrosion-causing water from tanks and monitor for corrosive environments.

Corrosion Control™ App

Get access to system data including Water Separator status, water levels, flow status, and more through the Corrosion Control™ Application, now standard on EVO™ 600 and EVO™ 6000 ATGs.

Corrosion Detection Sensor

The Corrosion Control™ Corrosion Detection Sensor provides proactive automated detection and preventative notification of a corrosive environment in the tank ullage space.

EVO™ Series Upgrade Kit

Get all the Corrosion Control System capabilities of the EVO™ 600 or EVO™ 6000 on an existing EVO™ 550 or EVO™ 5000 with the easy-to-install EVO™ Series Upgrade Kit.

The FFS PRO® Connect web interface allows you to securely connect directly to your EVO™ Series ATG from any web enabled device. It automatically scales for tablets and smart phones, meaning no app to download.

The EVO™ Series family of ATGs offers four different options with right-sized features to meet the requirements of your specific application, size, and compliance needs. Which ATG is right for your application?